snt

Syllabus

Mid-1 syllabus:

Text Books/ Weblinks

Books

Overview

Overview:

Unit-1: instrument, types of input, types of Response Sensors / Transducers

Unit-2: Motion, Dimension

Unit-3: Force, Flow, Pressure

Unit-4: Temperature, Liquid-level

Unit-5: Smart sensors: Characteristics, few Real-time Applications

Assignment Questions

UNIT-1

Quiz

Class Tests

Previous Papers

1

2

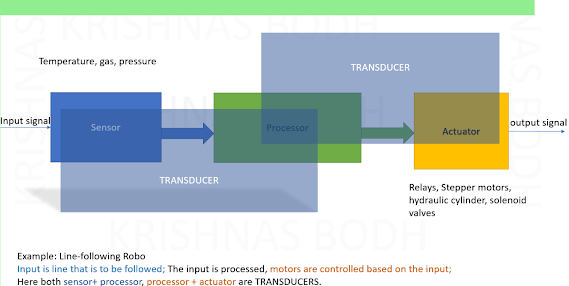

Unit-1: Instrument, types of input, types of Response Sensors / Transducers

Example of a Feedback system: Home heating instrument:

- A bimetallic will sense room temperature

- It helps in giving input to the controlling unit

- Controller will instruct the control element to maintain the temperature

- Hence the temperature is maintained as per predefined value.

- Generalized mathematical model of Measurement system

- Zero-order instrument

- a0, b0 are non-zero; remaining all are zeros.

- a0 qo = b0 qi

- qo = K qi where K = b0/a0 = sensitivity

- no distortion

- no time-lag

- Example: Potentiometer

- First-order instrument

- a1, a0, b0 are non-zero; remaining all are zeros.

- a1 dqo/ dt + a0 qo = b0 qi

- (𝜏D+1) qo = K qi

- 𝜏 = a1/a0 =time constant; K=b0/a0;

- Example: liquid-in-glass thermometer

- Step-response:

- Particular Solution = qopi = K qis

- Complementary Function = qocf = C e^(-t/𝜏)

- qo = K qis (1- e^(-t/𝜏) )

- settling time: After step input is applied, Time taken by a system to reach (+ or -tolerance) around its final value.

- Ramp response:

- qi = qis t

- qocf = C e^(-t/𝜏)

- (𝜏D+1) qo = K qis t

- qo = C e^(-t/𝜏) + K qis (t- 𝜏)

- qo = K qis [ 𝜏 e^(-t/𝜏) + t- 𝜏 ]

- Impulse response

- Impulse of strength A where lim p(t) with T-->0

- (𝜏D+1) qo = K A/T

- qo = ( KA/T ) (1- e^(-t/𝜏)) as T-->0

- i.e., qo = ( KA/𝜏 ) e^(-t/𝜏)

- Second-order instrument

Unit-2: Motion and Dimension Sensors

Potentiometer:

- Relative displacement:

- a wire (copper-nickel alloy) is wound on an insulator

- Maximum resistance between x and y position is R ohms.

- the position where jockey (Gold-silver) is placed on the wire where insulation is removed. This device is called Potentiometer.

- The conducting jockey position decides the resistance of the potentiometer.

- if jockey at position x; the potentiometer resistance is 0 ohms

- if jockey position at position below x; it varies as R/20, R/10 as the jockey moves downwards towards point y;

- if jockey is at point y; the potentiometer is having maximum resistance, i.e, R ohms

- There are different jockey shapes like circular, rectangular, etc.,

- The smallest voltage that can be measured is △V = V/n

- where V is applied voltage between x and y positions and n is number of turns (the wire wound along insulator)

- The jockey size must be appropriate such that, it does not short two or more wires at a time; This effects the precision.

- if the potentiometer is loaded, its linearity is effected.

- A potentiometer can also have a rotary motion as shown below:

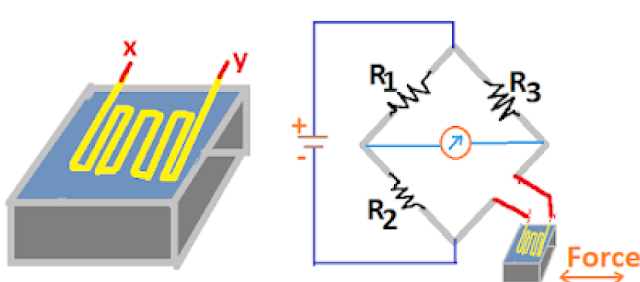

Resistance Strain gauges:

- There are no moving parts in bonded strain gauge.

- The strain-gauge is used in a bridge network which is already in a balanced state.

- The four arms are such that there is no deflection in the galvanometer.

- on an elastic material, a wire (thin film like) in the form of a coil/ foil/ is placed of different shapes. This is the default resistance.

- When force is applied, the material deforms and the wire stretches, making a change in the default resistance.

- when one of the arm resistance changes, causes the bridge unbalance. This unbalance causes deflection in galvanometer/ any other instrument which is used for calibration purpose.

- Gauge-factor= (ΔR/R)/ (ΔL/L)

- On a fixed base, there is a moving part in the middle.

- at two opposite different location unbonded wires are mounted with moving part and fixed base.

- When force is applied, Purple wires stretch; Black wire compress. This creates a change in resistance.

- Always a strain-gauge is used in a bridge network.

LVDT:

- Primary winding - P at the middle o Secondary winding which splits into two parts as:

- Secondary winding1 (S1) at one end of the chamber

- Secondary winding2 (S2) which is a part at the other end

- S1-P: this combination produces voltage V1

- S2-P: produces voltage V2

- A piston type Ferrite material based arrangement can move freely within the chamber.

- When Force is applied on the top surface of the piston

- Under stable condition (force not applied), piston stays at the center of the hollow chamber; This creates V1-V2= 0V;

- Force applied into chamber (PUSH): piston moves in towards S2 winding; This creates a potential V2 greater than V1

- Force applied out of chamber (PULL): piston moves out towards S1 winding; This creates a potential V1 greater than V2

- The piston moves linearly; this movement produces potential difference of two transformer windings; hence the name LINEAR VARIABLE DIFFERENTIAL TRANSFORMER

Synchros:

- Rotor has primary winding- P; it it attached to AC supply via slip-rings.

- Stator has three or more windings = Secondary Windings;

- here it is three; o namely S1, S2, S3. o each winding separated from other by 120°

- Primary coil (ferrite rod/core/ rotor) can be at :

- S2: it has a Voltage of 120° from S1 o S3: it has a Voltage of 240° from S1 and 120° from S2

- S1: no phase shift; as it is the reference location

- Synchros are of two types:

- Two synchros are coupled

- single AC supply

- Windings are electrically connected

- S11 to S21

- S12 to S22

- S13 to S23

- R1 rotor rotates for a torque applied;

- This moves at an angle θ1;

- the rotor R1 produces a field such that, rotor R2 if not oriented with R1, makes a similar angle movement (till it attains same rotational position as R1)

Capacitance transducers:

Piezo-electric transducers:

|

| piezo electric transducer |

|

| piezo connected to amplifier |

- The piezoelectric material has high stability.

- It is available in various shapes and sizes.

- The piezoelectric material has output insensitive to temperature and humidity.

- The piezoelectric material has high stability and hence it is used for stabilizing the electronic oscillator.

- The ultrasonic generators use the piezoelectric material. This generator is used in SONAR for underwater detection and in industrials apparatus for cleaning.

- It is used in microphones and speakers for converting the electric signal into sound.

- The piezoelectric material is used in electric lighter.

Electro-optical devices:

* Example1: LASER light is focused by a lens and depending on direct focus/ reflection, reaches the lens placed before the photo diode.

Nozzle – flapper transducers:

Digital displacement transducers:

Ultrasonic transducers:

Gyroscopic sensors:

Unit-3(1): Force, Flow measurement

Transducers For Force Measurement:

Bonded strain gauge transducers

Photo electric transducers

- LDR is an acronym for Light Dependent Resistor. LDRs are tiny light-sensing devices also known as photoresistors. An LDR is a resistor whose resistance changes as the amount of light falling on it changes. The resistance of the LDR decreases with an increase in light intensity, and vice-versa. This property allows us to use them for making light sensing circuits.

- The Light-dependent resistors made with photosensitive semiconductor materials like Cadmium Sulphides (CdS), lead sulfide, lead selenide, indium antimonide, or cadmium selenide and they are placed in a Zig-Zag shape as below; This shape can attract more light.

- The LDR has the highest resistance in dark around 1012 Ohm and this resistance decreases with the increase in Light.

- A photodiode is a PN-junction diode that consumes light energy to produce an electric current. They are also called a photo-detector, a light detector, and a photo-sensor.

- Photodiodes are designed to work in reverse bias condition.

- Typical photodiode materials are Silicon, Germanium and Indium gallium arsenide.

- A photodiode is subjected to photons in the form of light which affects the generation of electron-hole pairs. If the energy of the falling photons (hv) is greater than the energy gap (Eg) of the semiconductor material, electron-hole pairs are created near the depletion region of the diode.

- The electron-hole pairs created are separated from each other before recombining due to the electric field of the junction. The direction of the electric field in the diode forces the electrons to move towards the n-side and consequently the holes move towards the p-side. As a result of the increase in the number of electrons on the n-side and holes on the p-side, a rise in the electromotive force is observed.

- When an external load is connected to the system, a current flow is observed through it.

- Applications;

- Photodiodes are used in safety electronics such as fire and smoke detectors.

- Photodiodes are used in numerous medical applications. They are used in instruments that analyze samples, detectors for computed tomography and also used in blood gas monitors.

- Photodiodes are used in solar cell panels.

- Photodiodes are used in logic circuits.

- Photodiodes are used in the detection circuits.

- Photodiodes are used in character recognition circuits.

- Photodiodes are used for the exact measurement of the intensity of light in science and industry.

- A Phototransistor is a kind of transistor that is sensitive to light. It comprises of a photodiode & a transistor which is used to detect light and convert it into an electrical signal. The phototransistor was invented by John Northrup Shive in 1950 at Bell Telephone Laboratories.

- Its operation is based on the concept of the photoelectric effect. That is, when light is incident on a surface, the light energy is converted into electrical energy.

- Phototransistors are typically made up of a semiconductor material such as silicon or germanium, along with other materials that are used to form the various layers and junctions within the device.

- Advantages:

- High light sensitivity: They can detect even very small amount of light.

- They have high gain.

- It can be used as amplifiers: Since they are made of semiconductor material, they can act as a switch or amplifier. This means that the small current generated by the photodiode can be amplified to a larger current that can be easily measured or processed.

- Very cheap and easily available.

- Produce high current than photodiodes

- Disadvantages:

- Voltages over 1000 V cannot be handled by silicon-made phototransistors.

- Sensitive to surges, electrical spikes, and electromagnetic energy.

- Do not allow electrons to move freely as in other devices.

- Low-frequency response.

- Applications:

- Remote control systems to detect signals from remote controls, such as those used in TVs, DVD players, and other electronic devices.

- A photovoltaic (PV) cell, commonly called a Solar cell, is a nonmechanical device that converts sunlight directly into electricity.

- Some PV cells can convert artificial light into electricity.

- A photovoltaic cell is comprised of many layers of materials, each with a specific purpose. The most important layer of a photovoltaic cell is the specially treated semiconductor layer. It is comprised of two distinct layers (p-type and n-type), and is what actually converts the Sun's energy into useful electricity through a process called the photovoltaic effect.

- On either side of the semiconductor is a layer of conducting material which "collects" the electricity produced. Note that the backside or shaded side of the cell can afford to be completely covered in the conductor, whereas the front or illuminated side must use the conductors sparingly to avoid blocking too much of the Sun's radiation from reaching the semiconductor.

- The final layer which is applied only to the illuminated side of the cell is the anti-reflection coating. Since all semiconductors are naturally reflective, reflection loss can be significant. The solution is to use one or several layers of an anti-reflection coating (similar to those used for eyeglasses and cameras) to reduce the amount of solar radiation that is reflected off the surface of the cell.

- The most common material for commercial solar cell construction is Silicon (Si), but others include Gallium Arsenide (GaAs), Cadmium Telluride (CdTe) and Copper Indium Gallium Selenide (CIGS). Solar cells can be constructed from brittle crystalline structures (Si, GaAs) or as flexible thin-film cells (Si, CdTe, CIGS).

Variable reluctance pickup

Torque measurement dynamometers

Transducers For Flow Measurement:

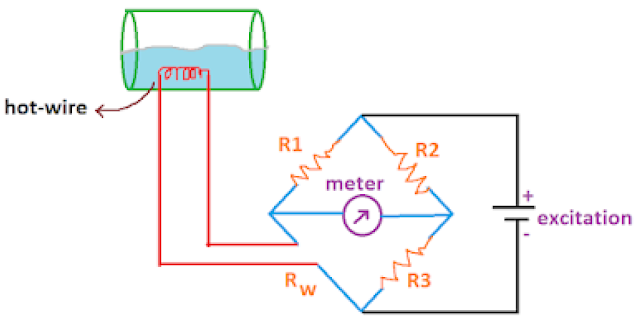

Hot wire and hot-film anemometers

Electromagnetic flow meters

Laser Doppler velocity meter

Unit-3(2): Pressure measurement

Transducers For Pressure Measurement:

Manometers

Elastic transducers (Liquid systems & gas systems)

Very High pressure transducers

Unit-4: Temperature measurement

syllabus: Transducers For Temperature Measurement: Thermal expansion methods, Thermometers (liquid in glass), pressure thermometers, Thermocouples, Materials configuration and techniques. Resistance thermometers, Thermistors, junction semiconductors, Sensors, Radiation methods, Optical pyrometers, Dynamic response of temperature sensors heat flux Sensors, Transducers for liquid level measurement, humidity, silicon and quartz sensors, fiber optic sensors

1a. BiMetallic Thermometers1b. Liquid-in-glass Thermometers1c. Pressure Thermometers

6a. Optical Pyrometers

Transducers For Temperature Measurement:

Thermal expansion methods

Thermocouples

Materials configuration and techniques

Resistance thermometers

Thermistors

Junction semiconductors sensors

Radiation methods & Optical pyrometers

Dynamic response of temperature sensors heat flux Sensors

6c(i) Operating conditions change ---> changes in numerical values or form of Transfer Function ---> loss of compensation

Heat-Flux sensors

Transducers for liquid level measurement

Transducers for humidity measurement

Silicon and Quartz sensors

Fiber optic sensors

Unit-5: Smart Sensors

Smart Sensors:

Introduction

Primary Sensors

Excitation, Amplification, Filters

Converters

Information Coding/Processing

Data Communication

The Automation

Sensors- Their Applications:

On-board Automobile Sensors (Automotive Sensors)

Home Appliance Sensors

Aerospace Sensors

Sensors for manufacturing

Sensors for Environmental Monitoring

impQ

1

2